SMEs in transformation and restructuring: Taking responsibility needs orientation!

Optimum dovetailing of measures increases efficiency by up to 20% - case study of special machine construction

Typical improvement approaches in SMEs include organizational competence, organizational efficiency, cash flow management, process optimization, etc., but only the correct interlinking and sequence of measures brings success - and often quickly.

This understanding is a core prerequisite for deriving a company (structure) and process (workflow) organization that is as conflict-free as possible, which can greatly increase the degree of interlocking of the company units and production steps and thus increase efficiency enormously.

The optimally interlinked use of resources becomes the cash flow driver.

Careful planning, active, convincing communication and control are the key to success. The steps involved:

- Problem identification in dialog with shareholders and management

- Definition of (strategic) challenges to ensure sustainable efficiency

- Top-line optimization approaches for positioning the service portfolio and growth

- Optimization of the supply/value chain through supply chain and purchasing improvements

- Working capital-driven cash flow optimization

- Task force for active implementation of solutions

- If necessary, consultants also enter management on an interim basis

In order to rapidly improve the top and bottom line, we increase efficiency in existing processes ("Save Money") and optimize the product portfolio with innovations for sustainable growth ("Make Money").

"Save money" measures for existing processes typically include

- Improvement of throughput times/set-up times

- Reducing the reject rate -> improving the production result

- Reduction of stock levels

- Design-to-cost projects

- Identification of resource improvements, e.g. better quality material

"Make money" project steps frequently observed are

- Pricing strategies for customer or market segments

- Development of new markets

- Improving delivery capability

- Development of technologies, including incremental innovations

- Initiatives for non-incremental product improvements, i.e. innovations with a "breakthrough" character.

A case study may illustrate this.

Initial situation: A traditional, family-run German company in special machine manufacturing with over 150 years of history. Despite its high quality, it showed tendencies towards costly "overengineering". Significant losses in previous years, due to high fixed costs and a suboptimal pricing policy, were exacerbated by a lack of understanding of customer needs and technology trends at the time, as well as inefficient internal processes.

Approach:

- Analysis of the current situation and identification of key challenges

- Definition of specific "modules", dovetailing of transformation steps with our "PIPE" tool: Projects Improving Profit & Efficiency

- Rapid elaboration of prioritized measures and implementation in the form of work packages

- Weekly progress review

- Constant communication and support for acceptance of the changes

The project began in Q4/22 with an analysis of the current situation, joint planning of the upcoming tasks "at eye level" and the definition of the work packages (1) R&D, (2) purchasing, (3) sales and (4) PMO, which was followed by the implementation of the work packages and new projects in Q1/23. In Q3/23, the planned interim targets were achieved: process changes and new projects were being implemented with constant support and were finally successfully completed in Q4/23 and Q1/24.

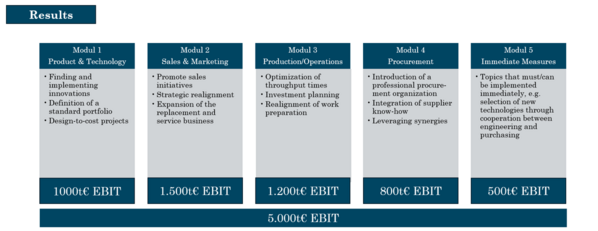

Results

The result for this special machine manufacturer is convincing: the improvements were achieved sustainably from a dramatically poor situation. The breakdown of the work packages (see illustration below, click to enlarge) shows the financial successes.

Are you facing similar challenges in the SME sector? Feel free to contact us - either the author directly or any of our Senior Advisors in your area. The PDF download for this case is available here (in German).